helical end mills feeds and speeds

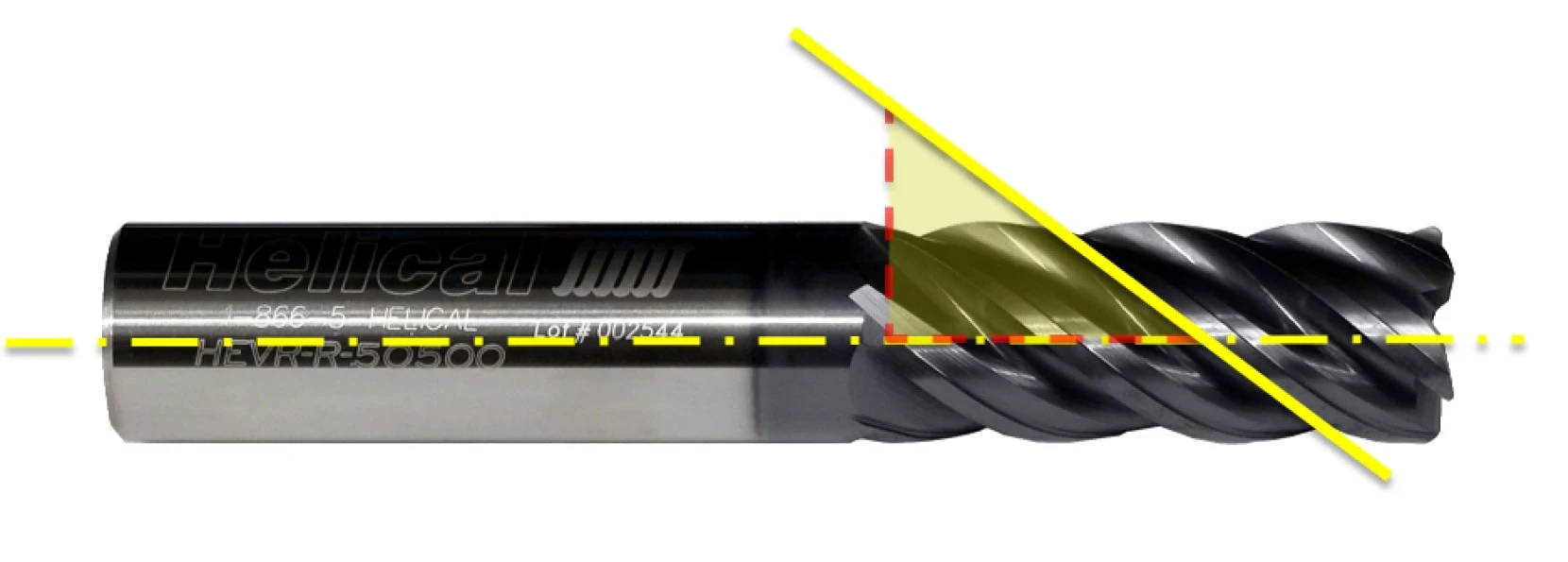

Simply search for your tool number and then click on Speeds Feeds in the resources section. A flat-ended chamfer cutter with helical flutes has a tip diameter of 060.

End Mill Tool With High And Low Helical Flutes And Related Method For Rough Cutting And Finishing A Workpiece Destiny Tool

Calculate Feed IPM FPT x Number of Flutes X RPM.

. Combination Feed HEM - 5 Flute - Chipbreaker Rougher - Variable Pitch This offering of High Feed End Mills used for both high feed and High Efficiency Milling HEM applications features tooling with offset chipbreaker geometry for optimal chip evacuation minimized harmonics and reduced tool pressure. Below are 5 things that all machinists should know about this exciting Helical Solutions product offering. Our Engineers Are Always Available to Help.

Using Machining Advisor Pro is a no brainer its a standard. Please be advised that published lead times may not be accurate for HTC. Using current input - Data results are for External Helical Interpolation.

Ingersoll supplies almost all my carbide insert tooling and I asked him about the Ingersoll carbide end mills. A customer can find the SFM for the material on the left in this case 304 stainless steel. Ad Chance Products Are the Proven Solution.

Quick Navigation CNC Machining Top. They excel in applications with light axial depths of cut. Harvey Tool provides the following chart for a 18 diameter end mill tool 50308.

Im going to cut threads a 12 deep in one pass so I will set my Cut Depth to 0500. Find RPM at intersection of SFM Diameter. Matters more as material machinability decreases.

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. Machining Advisor Pro paired with Helical End Mills is the Holy Grail of End Mill Performance. Determine the spindle speed RPM and feed rate IPM for a milling operation as well as the cut time for a given cut length.

Use the light roughing as described at the bottom of the chart. Speeds and feeds charts for end mills from The Carbide End Mill Store. Helicals fully stocked offering of High Feed End Mills is designed for outstanding performance and maximum feed rates in aluminum and non-ferrous materials.

ContactFoundation Technologies Get Started. A feature on a variety of high. We can look that up on G-Wizards Thread Tab.

This blog covers speeds and feeds for milling. I would use a 58 WhisperKut from Dura-Mill. Material HBRc Speed SFM Uncoated Speed SFM ALTiN Feed Inches Per Tooth Tool Diameter032-056059-090100-190200-350370-595600 Cast Iron.

Posted on January 31 2018 Leave a comment. Government regulations require that safety glasses be worn during use. SFM FPT For Material 2.

SURFACE FEET PER MINUTES. I am creating a new calculator based on your feedback. We cut slots all day long in 4140.

Helical speeds and feeds. 31 rows Geometry proven to achieve maximum feed rates in steels up to 45 Rc. Part of what makes Helical tools worthwhile is the.

They should also shorten your run time too. The Speeds and Feeds Calculator may be employed for calculations of estimated speeds and feeds RPM and IPM values on the basis of the parameters you have currently set based on your tools and stock material. Choose a type of operation drilling reaming boring counterboring face milling slab millingside milling end milling or.

Cut Depth is the difference between major and minor diameter of a 12-20 thread. Enter Cut Depth and Cut Width. No hard fast rule there but.

Please fill out the form below with feeds and speeds that work for you and I will place them into a new database for all to use. Cm Number of circularhelical tool path revolutions. Maximum depth per rev depends on the material toolhole diameter ratio tool and other factors.

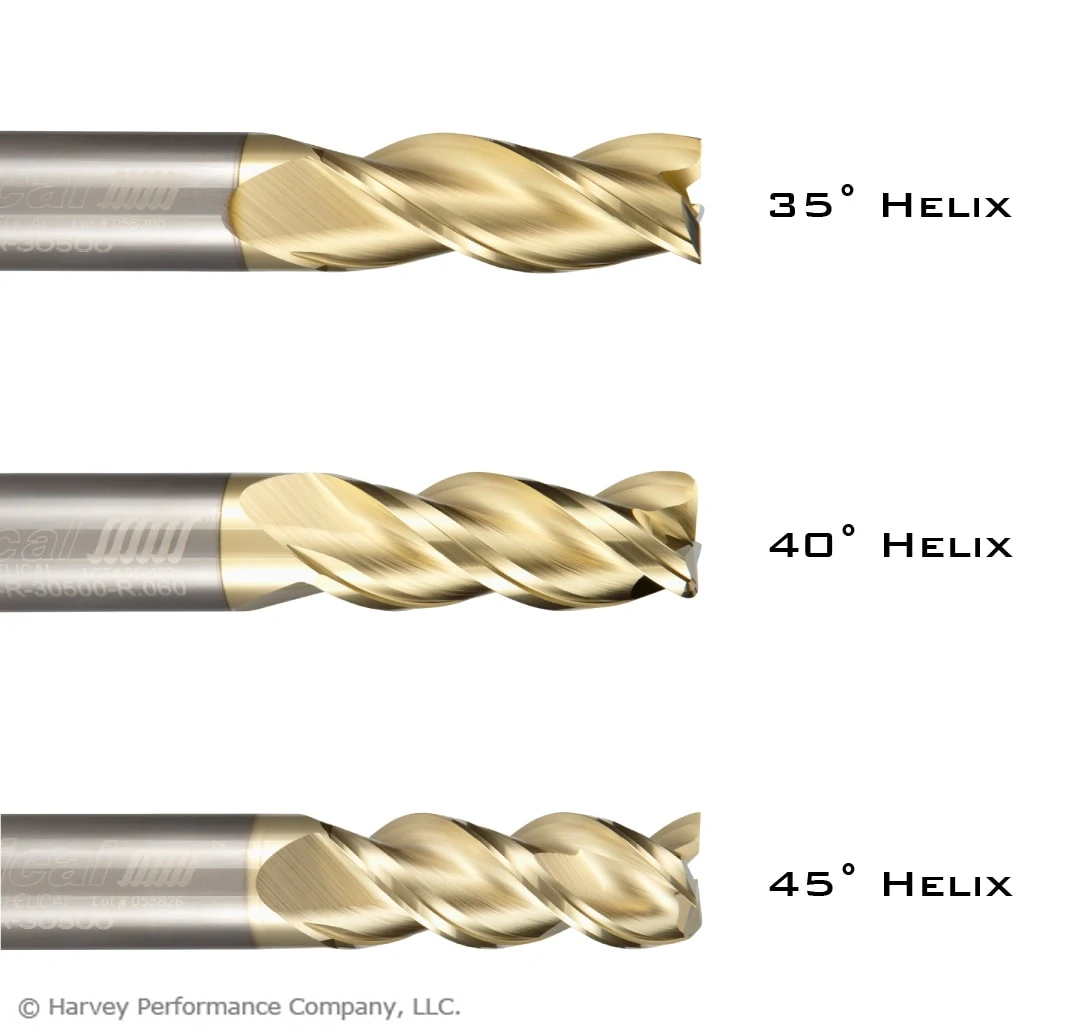

Helical end mills feeds and speeds Friday May 6 2022 Edit High Helix Carbide End Mill At Rs 3000 Unit Solid Carbide End Mills Id 20478637012 Series 6774 Inch Rf100 Speed 4 Fl Extra Length End Mill Guhring 4 6 Flute High Feed End Mills Epic Tool. Using MasterCam dynamic milling and whisperkuts end mills. Its reduced neck geometry provides maximum strength in long reach and deep pocketing applications while its end profile provides optimal tool engagement and reduced cutting forces.

Speeds and Feeds 101 October 2. MAP is our go-to solution for High Efficiency Milling and has exponentially decreased our run times as well as increased our tooling life. Need Advice On Your Project.

New Helical Machining Advisor Pro. Dura-Mills WhisperKut Speed and Feed High Performance End. Check out the speeds and feeds chart.

Milling Speed and Feed Calculator. In addition to our Speeds Feeds Library you can also find specific running parameters directly on our product page and tool details page for every tool. 1-888-868-5988 Technical Support Email.

Speeds and feeds speeds and feeds for key cutters material plastic magnesium aluminum copper brass bronze cast iron steel titanium stainless nickel monel inconel waspaloy hastelloy type teflon nylon phenolic glass filled azamezzehk 2021 thru 6061 101-707 834-978 gray ductile malleable 1005-1029 1030-1055 1060-1095 10l45-10l50 12l13-12l15. Combination Feed HEM - 5 Flute - Chipbreaker Rougher - Variable Pitch This offering of High Feed End Mills used for both high feed and High Efficiency Milling HEM applications features tooling with offset chipbreaker geometry for optimal chip evacuation minimized harmonics and reduced tool pressure. View Speeds Feeds.

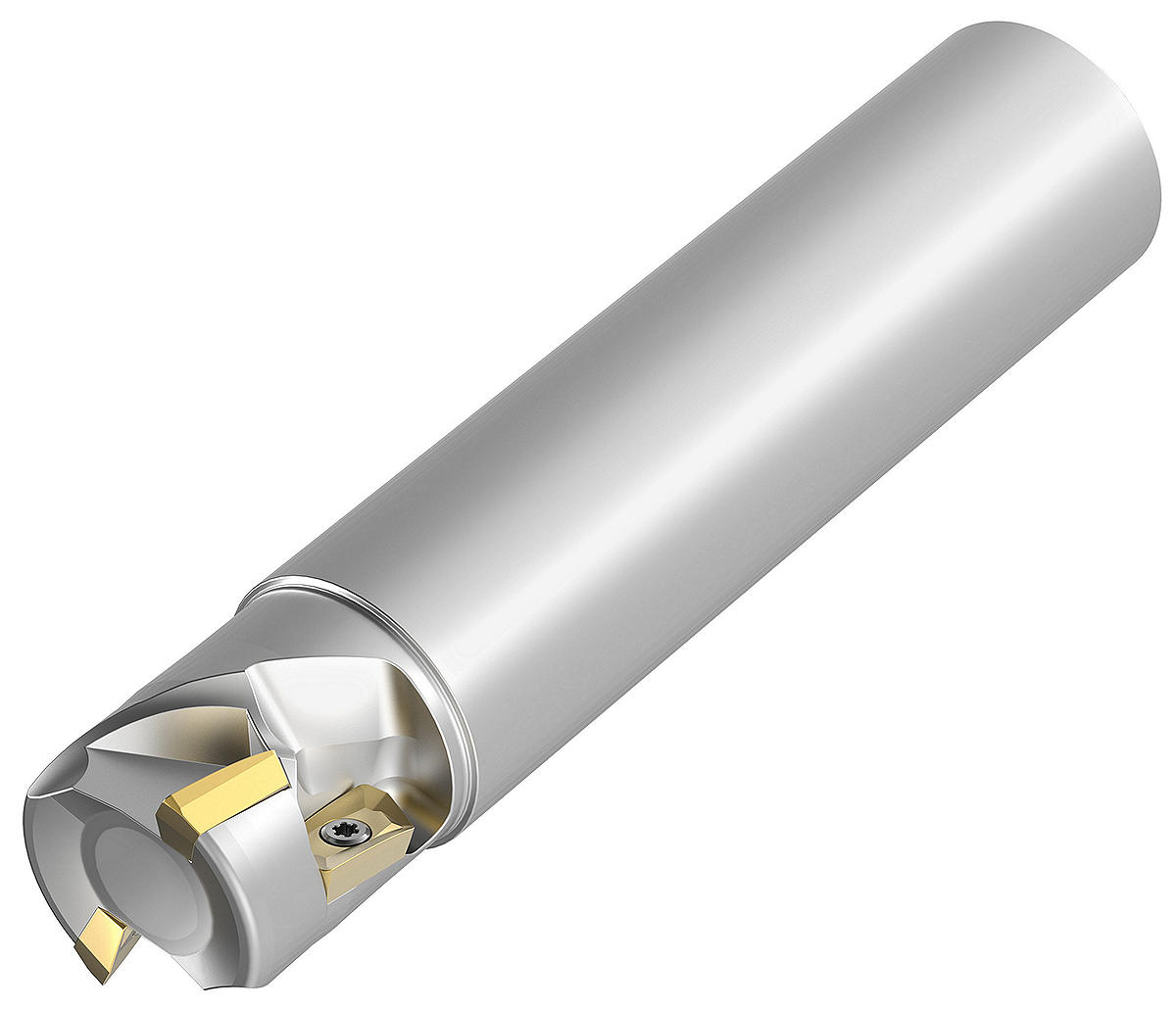

A High Feed End Mill is designed to take a large radial depth of cut 65 to 100 of the cutter diameter with a small axial depth of cut 25 to 5 diameter depending on the. All cutting tools can shatter and break during use. Therefore many orders are being delayed from normal lead times.

Convert linear feed to tool center feed to determine the feedrate. Basically what it boiled down to was stick with Helical. Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth such as an end mill or face mill.

Determining the right speeds and feeds for your tool and operation can be a complicated process but understanding the ideal speed RPM is necessary before you start running your machine to ensure proper tool life. Aph Z-axis depth for one helical revolution circular 0 in. End Mill Speed Feed Calculator.

Dear Customers Our supplier HTC is having substantial problems with supply chains due to Covid-19. Calculations use the desired tool diameter. Speeds and Feeds Master Library of Harvey Tools entire tool line up of Specialty End Mills Drills and Cutting Tools.

Variable Helix End Mills for Aluminum Alloys - Chipbreaker Roughers - Square The unique geometry of this solid carbide 3 flute Harvey Tool features a variable pitch design and chipbreaker geometry for reduced chatter and harmonics increased MRR and improved chip management while machining aluminum. Manufacturing Engineer Waynesburg PA. Running a tool too fast can cause suboptimal chip size or even catastrophic tool failure.

Global Cutting Tools End Mills Cutting Tools Metalworking Extreme3

Yg 1 50573 Carbide Ball Nose End Mill Inch Long Length Uncoated Bright Finish 30 Degree Helix 2 Flutes 3 Inch Overall Length 0 25 Inch Cutting Diameter 0 25 Inch Shank Diameter Amazon Ca Industrial Scientific

Global Cutting Tools End Mills Cutting Tools Metalworking Vortex5

Specification Variable Helix End Mill

Series 6773 Inch Rf100 Speed 4 Fl Std Length End Mill Guhring

Helical Solutions Archives Harvey Performance Company

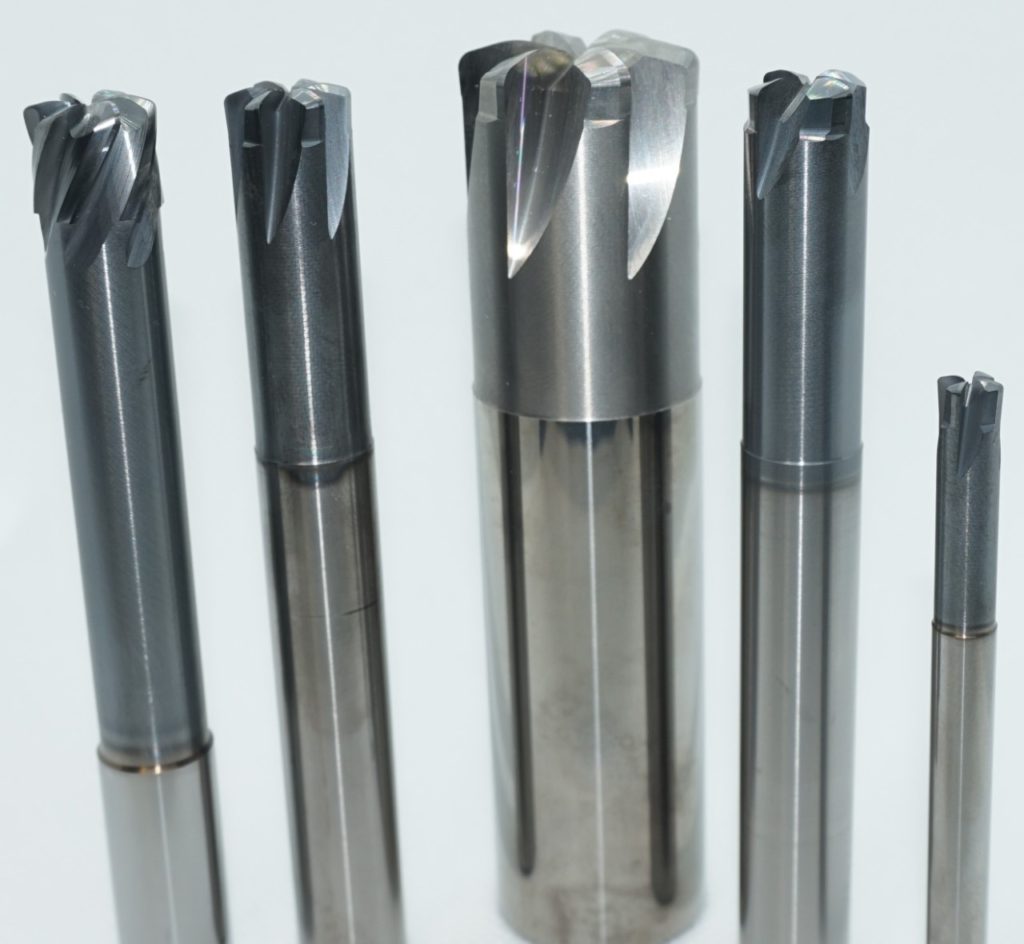

Necked Tooling Archives Harvey Performance Company

Zrn Coated 3 16 Dia 3 Flute High Helix Carbide Rougher X 625 Loc Maritool

End Mills With Diameter 20 Mm For Milling Experiments A End Mill With Download Scientific Diagram

Cutting Tools Good Vibrations Blog Resources

End Mill An Overview Sciencedirect Topics

Solid Carbide End Mill Grades Geometries And Coatings

4 6 Flute High Feed End Mills Epic Tool

Mill 1 10 Helical Indexable Helical End Mills

End Mill An Overview Sciencedirect Topics

Helix Diameter Archives Harvey Performance Company

Basic End Mills Technical Information Msc Industrial Supply Co